QuietLine® Barrier Walls

For any place noise is a problem, QuietLine is the solution

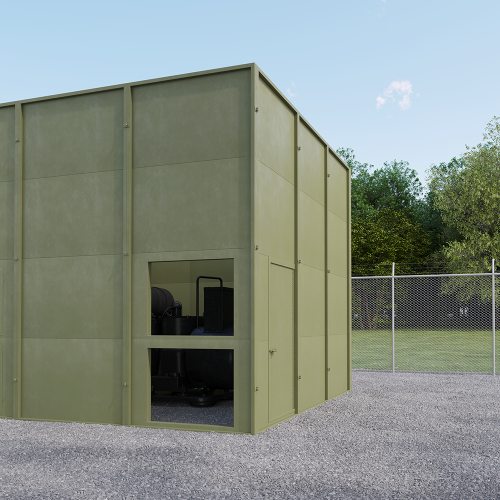

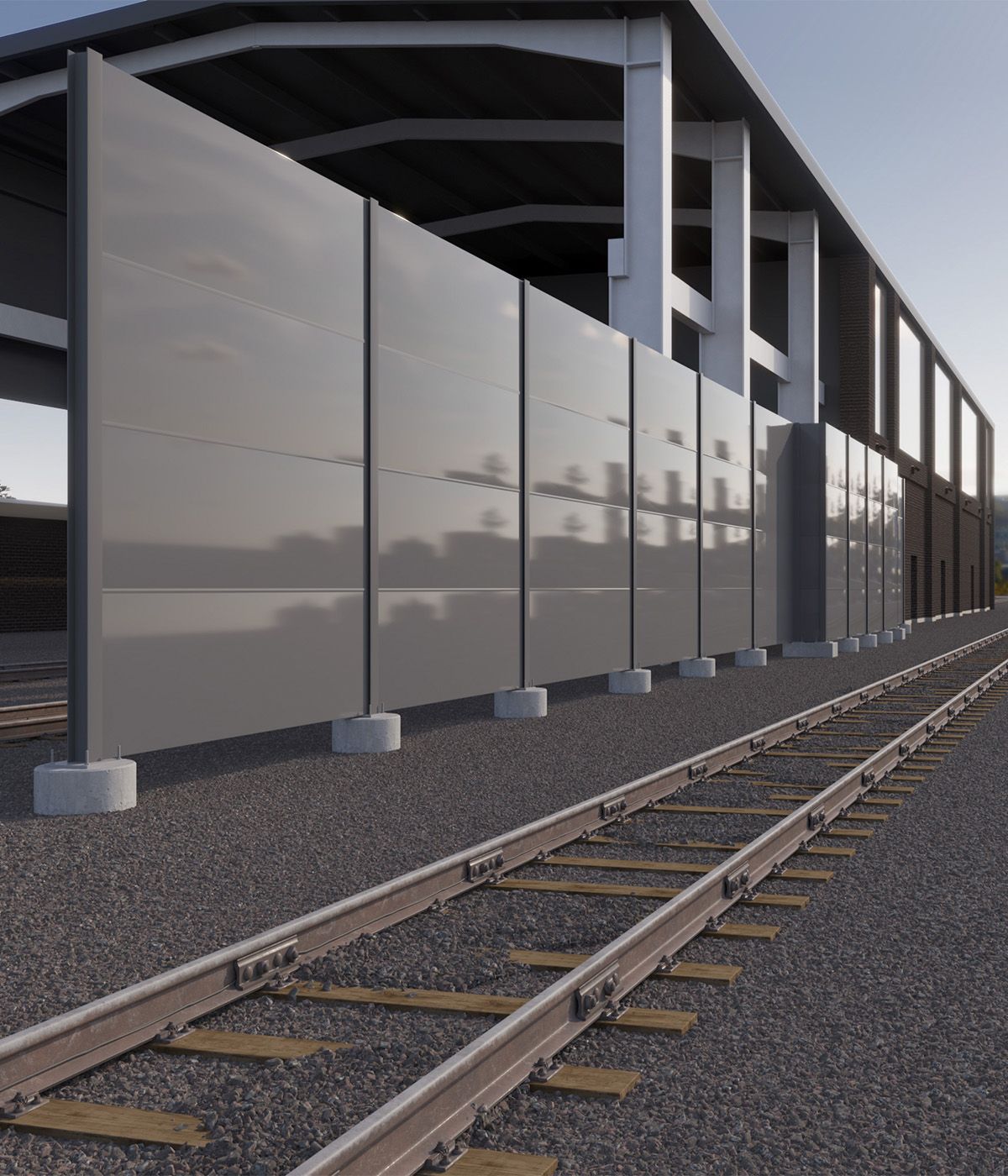

Barrier Walls are normally used to place a sound barrier between a noise source and a sensitive receiver. This barrier creates a "sound shadow" zone of quiet that can be tailored to cover almost any size area either indoors or out. Absorptive noise control barriers provide maximum noise reduction with lightweight modular panels and/or louvers.

Our design services include layout, structural steel support framework, foundation design (for ground level barriers), access doors, sound control louvers and certified calculations including P.E. or S.E. stamp. Perfect for new construction or retrofit to an existing structure.

Literature

QuietLine V-Stack

The Easier, Safer Way to Build Noise Barrier Walls.

Noise Barriers manufactures and packages our noise barrier wall systems with the installation task in mind. We make it very simple to hook our panels while still in the crate, making it less manpower intensive and safer for the installing crew as compared to other systems.

Features

- Free-Standing or Elevated Panel Construction

- Allows for maximum flexibility of design and utility on the ground or on the rooftop

- One– or two-sided sound absorption

- Steel or aluminum construction

- Perfect for retrofit installation to solve existing noise problems

- Low-weight construction ideal for roof or bridge mounted applications

- Designed to withstand high wind loads

- Durable

- Galvanized, aluminum, or stainless steel

- Two, four, or five-inch thicknesses

- Easy installation and removal

- Horizontal or vertical installation

- Self-draining

- Maximum acoustical performance

- All products independently tested (STC 37 above, NRC 0.95 above)

- Weather resistant

- Graffiti resistant

- Unlimited color selection

Applications

- HVAC Mechanical Equipment

- Salvage Yards

- Loading Docks

- Power Plants

- Rail Yards

- Highways

- Generators/Compressors

- Carwashes

- Transformers

- Manufacturing Facilities

Acoustic Performance - Specifications - Drawings

Sound Transmission Loss Data, dB

| Octave Band Center Frequency, Hz | 125 | 250 | 500 | 1K | 2K | 4K | STC | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Barrier Panels | |||||||||||||||||||

| V-Stack Aluminum | 14 | 20 | 31 | 42 | 40 | 52 | 33 | ||||||||||||

| V-Stack Steel | 22 | 26 | 35 | 45 | 47 | 48 | 38 | ||||||||||||

| Type SL | 18 | 26 | 35 | 45 | 49 | 52 | 37 | ||||||||||||

| Type SL-R | 18 | 26 | 35 | 45 | 49 | 52 | 37 | ||||||||||||

| Type SL-R Concealer | 18 | 26 | 35 | 45 | 49 | 52 | 37 | ||||||||||||

| H/P 42 V-Stack | 23 | 31 | 40 | 49 | 56 | 62 | 42 | ||||||||||||

| H/P 38 | 24 | 25 | 33 | 43 | 50 | 55 | 38 | ||||||||||||

| H/P 42 | 23 | 31 | 40 | 49 | 56 | 62 | 42 | ||||||||||||

| H/P 44 | 27 | 34 | 41 | 46 | 53 | 59 | 44 | ||||||||||||

| H/H 50 | 26 | 44 | 50 | 54 | 57 | 64 | 50 | ||||||||||||

| H/H 52 | 37 | 43 | 47 | 53 | 54 | 57 | 52 | ||||||||||||

| All tests performed by an independent NVLAP accredited acoustical testing facility. The test method conforms with ASTM Designations E90-99 or E90-02 and E413-87. | |||||||||||||||||||

| Octave Band Center Frequency, Hz | 125 | 250 | 500 | 1K | 2K | 4K | NRC | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Sound Absorption Coefficients Barrier Panels | |||||||||||||||||||

| V-Stack Aluminum | 0.89 | 1.23 | 1.18 | 1.08 | 1.06 | 0.95 | 0.95 (1.15) | ||||||||||||

| V-Stack Steel | 0.86 | 1.20 | 1.17 | 1.07 | 1.08 | 1.02 | 0.95 (1.15) | ||||||||||||

| Type SL (All Models) | 0.92 | 1.15 | 1.22 | 1.13 | 1.08 | 1.04 | 0.95 (1.15) | ||||||||||||

| H/P 42 | 0.68 | 1.06 | 1.12 | 1.08 | 1.03 | 0.98 | 0.95 (1.05) | ||||||||||||

| All tests performed by an independent NVLAP accredited acoustical testing facility. The test method conforms with the requirements of the ASTM Standard Test Method for Sound Absorption and Sound Absorption Coefficients by the Reverberation Room Method: ASTM C423-90a and E795-00. | |||||||||||||||||||

Type SL

This panel has a solid skin on one side and a sound absorptive skin on the other side. 5” thick, 14 gauge solid skin with a 20 gauge perforated skin. Perforated skin has 3/32” diameter holes on 3/16” staggered centers. Weight: 6.0 lbs./sq.ft. All galvanized construction using “paint ready” galvanneal A-60 steel. THE “SHIP-LAP” DESIGNED PANELS STACK HORIZONTALLY ONE ON TOP OF ANOTHER BETWEEN COLUMNS. Maximum length 192”. The acoustic fill is non-combustible, sound absorbing fiberglass or mineral wool. Prime painting or factory finish powder-coating is available.

Click Icon to Download File

Specifications:

Type SL-R

This panel has a solid skin on one side and a sound absorptive skin on the other side. 5” thick, 14 gauge solid skin with a 20 gauge perforated skin. Perforated skin has 3/32” diameter holes on 3/16” staggered centers. Weight: 6.0 lbs./sq.ft. All galvanized construction using “paint ready” galvanneal A-60 steel. THE “SHIP-LAP” DESIGNED PANELS STACK HORIZONTALLY ONE ON TOP OF ANOTHER BETWEEN COLUMNS CREATING A- 1” REVEAL between panels. Maximum length 192”. The acoustic fill is non-combustible, sound absorbing fiberglass or mineral wool. Prime painting or factory finish powder-coating is available.

Click Icon to Download File

Specifications:

SL-R Concealer™

This panel has a solid skin on one side and a sound absorptive skin on the other side. 5” thick, 14 gauge solid skin with a 20 gauge perforated skin. Perforated skin has 3/32” diameter holes on 3/16” staggered centers. Weight: 6.0 lbs./sq.ft. All galvanized construction using “paint ready” galvanneal A-60 steel. The concealer design stacks horizontally and between columns in such a manner as to create a uniform 1” reveal between each panel both horizontally and vertically, with no visible structural steel. Maximum length 192”. The acoustic fill is non-combustible, sound absorbing fiberglass or mineral wool. Prime painting or factory finish powder-coating is available.

Click Icon to Download File

Specifications:

V-Stack®

The V-Stack is Noise Barriers most versatile panel system. This panel has a solid skin on one side and a sound absorptive skin on the other side. The panel is 4” or 5” thick depending on span and wind-loading, 16 gauge solid skin with a 22 gauge perforated skin. Perforated skin has 3/32” diameter holes on 3/16” staggered centers. Weight: 5.2 lbs./sq.ft. All galvanized construction using “paint ready” galvanneal A-60 steel with internal stiffeners 24” on center. The face sheets are spot welded to the panel framing channel. All stiffeners and panel channel framing is minimum 18 gauge steel. THE PANELS CAN BE INSTALLED VERTICALLY OR STACK HORIZONTALLY ONE ON TOP OF ANOTHER BETWEEN COLUMNS. Panels lift out of the crate without handling and install without fasteners. Maximum panel size 60” x 190”. The acoustic fill is non-combustible, sound absorbing fiberglass or mineral wool. Prime painting or factory finish painting is available.

Click Icon to Download File

Specifications:

Model H/P

This panel has a solid skin on one side and a sound absorptive skin on the other side. 4” thick, 16 gauge solid skin with a 22 gauge perforated skin. Perforated skin has 3/32” diameter holes on 3/16” staggered centers. Weight: 5.2 lbs./sq.ft. All galvanized construction using “paint ready” galvanneal A-60 steel with internal stiffeners 24” on center. The face sheets are spot welded to the panel framing channel. All stiffeners and panel channel framing is minimum 18 gauge steel. THE PANELS CAN BE INSTALLED VERTICALLY OR STACK HORIZONTALLY ONE ON TOP OF ANOTHER BETWEEN COLUMNS. PANEL IS CONNECTED TO PANEL WITH AN “H” JOINER. Maximum length is 168”. The acoustic fill is non-combustible, sound absorbing fiberglass or mineral wool. Prime painting or factory finish painting is available.

Click Icon to Download File

Specifications

Drawings (General):

Model H/H

This panel is reflective both sides (non-absorptive). 4” thick, 16 gauge solid skin with a 16 gauge solid skin. Weight: 6.7 lbs./sq.ft. All galvanized construction using “paint ready” galvanneal A-60 steel with internal stiffeners 24” on center. The face sheets are spot welded to the panel framing channel. All stiffeners and panel channel framing is minimum 18 gauge steel. THE PANELS CAN BE INSTALLED VERTICALLY OR STACK HORIZONTALLY ONE ON TOP OF ANOTHER BETWEEN COLUMNS. PANEL IS CONNECTED TO PANEL WITH AN “H” JOINER. Maximum length is 168”. The acoustic fill is non-combustible, sound absorbing fiberglass or mineral wool. Prime painting or factory finish painting is available.

Click Icon to Download File

Specifications:

2" or 4" Cladding Panels

2" Thick Panels: This panel is 2” thick x 18” wide x up to 144” long. The perforated pattern is 3/32” holes on 3/16” staggered centers. The panel is constructed of 22 gauge galvanized perforated steel (A-60 Galvanneal if finish painted, G-90 spangled galvanized steel if un-painted).

4" Thick Panels: This panel is 4” thick x 14” wide x up to 144” long. The perforated pattern is 3/16” holes on 3/32” staggered centers. The panel is constructed of 22 gauge galvanized perforated steel (A-60 Galvanneal if finish painted, G-90 spangled galvanized steel if un-painted).